The OdaVent® MHV biofilter is an industry-leading, below-ground odour treatment system which can be installed unobtrusively in street verges or other areas with limited space, or simply where a more aesthetically pleasing solution is desirable. OdaTech® MHVs can be configured to treat flow rates from 50 to 600 cubic metres per hour passively or force vented at discharge manholes, main sewers and other odorous sites. The below-ground OdaVent® units are also ideal for venting and treating the foul gases discharged from air valves to prevent H2S induced concrete corrosion at air-valve locations and pressure main failures thus saving thousands of dollars in costly infrastructure repair and refurbishment.

Odatech® produces a comprehensive range of engineered, highly efficient and cost-effective odour control systems specifically designed and developed for odour removal and corrosion prevention for municipal and industrial applications.

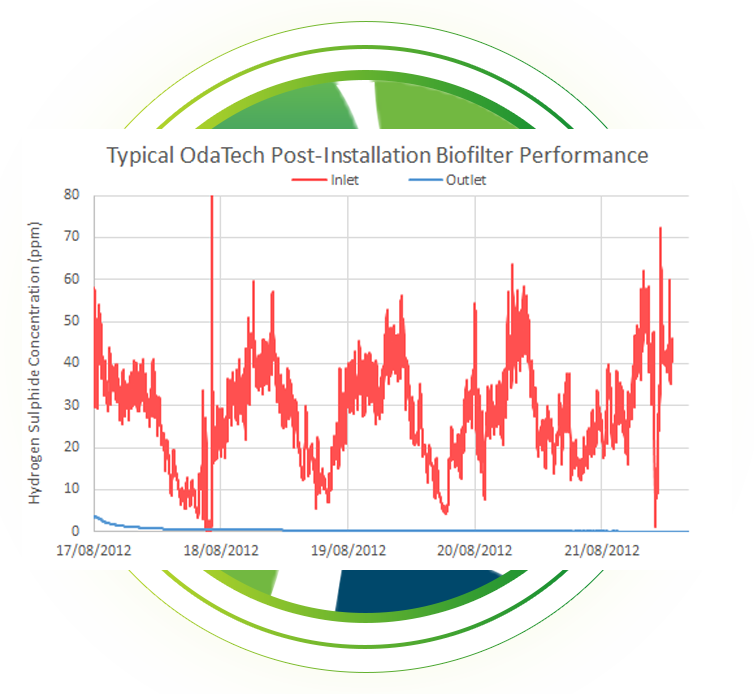

The OdaVent® biofilter uses an innovative, patented design to biologically oxidise hydrogen sulphide (H2S) and volatile organic compounds (VOCs). The aerobic bacteria (thiobacillus thiooxidans) which live in OdaTech’s proprietary biomedia blend break down odorous compounds in the foul gas stream as it flows through the biofilters. Each stage of biofiltration treatment removes 95%+ of hydrogen sulphide, and OdaTech odour control systems are designed to treat 99%+ of hydrogen sulphide in the air stream. All systems are modular and expandable which allows customised systems to be simply configured for different applications, flowrates and removal efficiency expectations.

Unlike a traditional open bed biofilters, the fully-enclosed nature of Odatech’s system allows the treatment conditions to be carefully controlled to ensure optimal ecological conditions for the long-term survival of the biologically active bacteria in the biomedia. This results in a consistently >99% reduction in hydrogen sulphide levels.

The OdaVent’s innovative design prevents biomedia compaction, water logging and airflow channelling which together with its specially blended and optimised biomedia extends media life to beyond 3 years. Media replacement is simple and downtime is contained to less than a day.

Each stage of biofiltration treatment removes >95% of hydrogen sulphide, and a complete OdaTech odour control system is designed to reduce foul odours to undetectable levels. The graph to the right shows the performance of an OdaTech® system in Fremantle in the days soon after biomedia was installed. The outlet concentration dropped to below one part per million after only twelve hours of operation, and less than 0.1ppm after three days, with inlet peak hydrogen sulphide concentrations of 70ppm recorded in that time.

OdaTech products have been specifically developed and used Australia wide to resolve odour and corrosion problems at waste water collection and transfer infrastructure such as pumping stations, ischarge manholes, sewage air-valve pits and inlet works at waste water treatment plants. Their consistent high odour removal performance and low operational costs with no hazardous wastes are some of the benefits seen by many water utilities to opt for OdaTech systems for mitigating odours at problem sites.

The root cause of odours and corrosion in sewer collection systems is sulphide generation by bacteria in waste water passing through sewer pipes and infrastructure. The gas released by this bacteria – hydgrogen sulphide (“rotten egg gas” – H2S) is the primary cause of odours in sewer infrastructure. Another type of aerobic bacteria then utilises the H2S gas in the head space of the sewer infrastructure to produce sulphuric acid (H2So4) which corrodes concrete causing damage wastewater pipes and facilities. In severe situations, sewer pipe and manhole failures and collapses can result in disruption of services and uncontrolled releases of waste water into the environment. Damage such as this can result in repair costs in the millions of dollars.

Rather than allowing the build-up of H2S gas in the sewer infrastructure, an OdaTech

force-ventilated odour control system continuously extracts air from the head space, preventing corrosion while also eliminating complaints from nearby residents. Feel free to contact us or request for a quote.